Digital Scans

Modern dentistry begins with digital precision. Alpine Dent Lab operates a fully digital workflow that minimizes manual steps and maximize s repeatability, resulting in restorations that fit predictably and require fewer chairside adjustments.

We accept intraoral scans from all major scanner brands and file formats, including open STL and native files when needed. Incoming files are verified by our digital intake team for scan completeness, margin clarity, and occlusal relationships; any issues are flagged to the sending clinician with clear guidance for re-scanning. Encrypted transfer and secure cloud portals protect patient data while keeping case files accessible to assigned CAD designers and production managers.

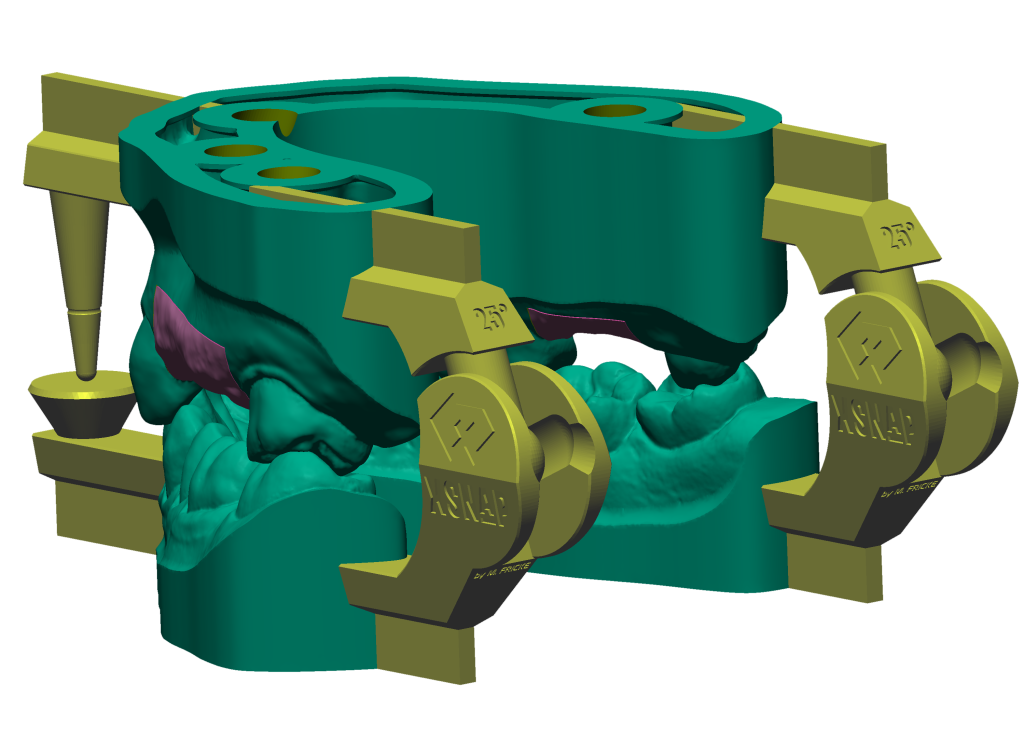

Our CAD team applies evidence-based design principles focused on margin integrity, appropriate cement space, anatomically correct occlusion, and contours that facilitate natural emergence profiles. Designs undergo a two-step review—automatic software checks followed by an experienced technician’s visual review—before manufacturing. Production uses micron-accurate 5-axis milling and high-resolution 3D printing, combined with validated sintering and finishing protocols to ensure consistent strength and aesthetics.

For clinics, the benefits are tangible: no more shipping physical models, faster turnaround, fewer remakes, and real-time case tracking. We offer downloadable prep and scanning guides, short video tutorials for optimal scan capture, and priority scan-check feedback so cases can move to design and production without delay.